Custom Engineered Solutions

Since its founding, Thermal Engineering Corporation (TEC) has been a leader in the advancement of applied heat transfer technologies, with over 90 patents awarded to date.

Recognized as a pioneer in industrial oven design, TEC introduced groundbreaking systems such as the Turbulator Oven, Radiant Wall Oven, and Air Radiant Oven—technologies that transformed finishing processes worldwide. These innovations significantly improved coating quality, reduced energy consumption by millions of dollars annually, and minimized required installation footprints.

At TEC Process, we continue this tradition of innovation by collaborating closely with customers to engineer custom solutions tailored to their specific application requirements.

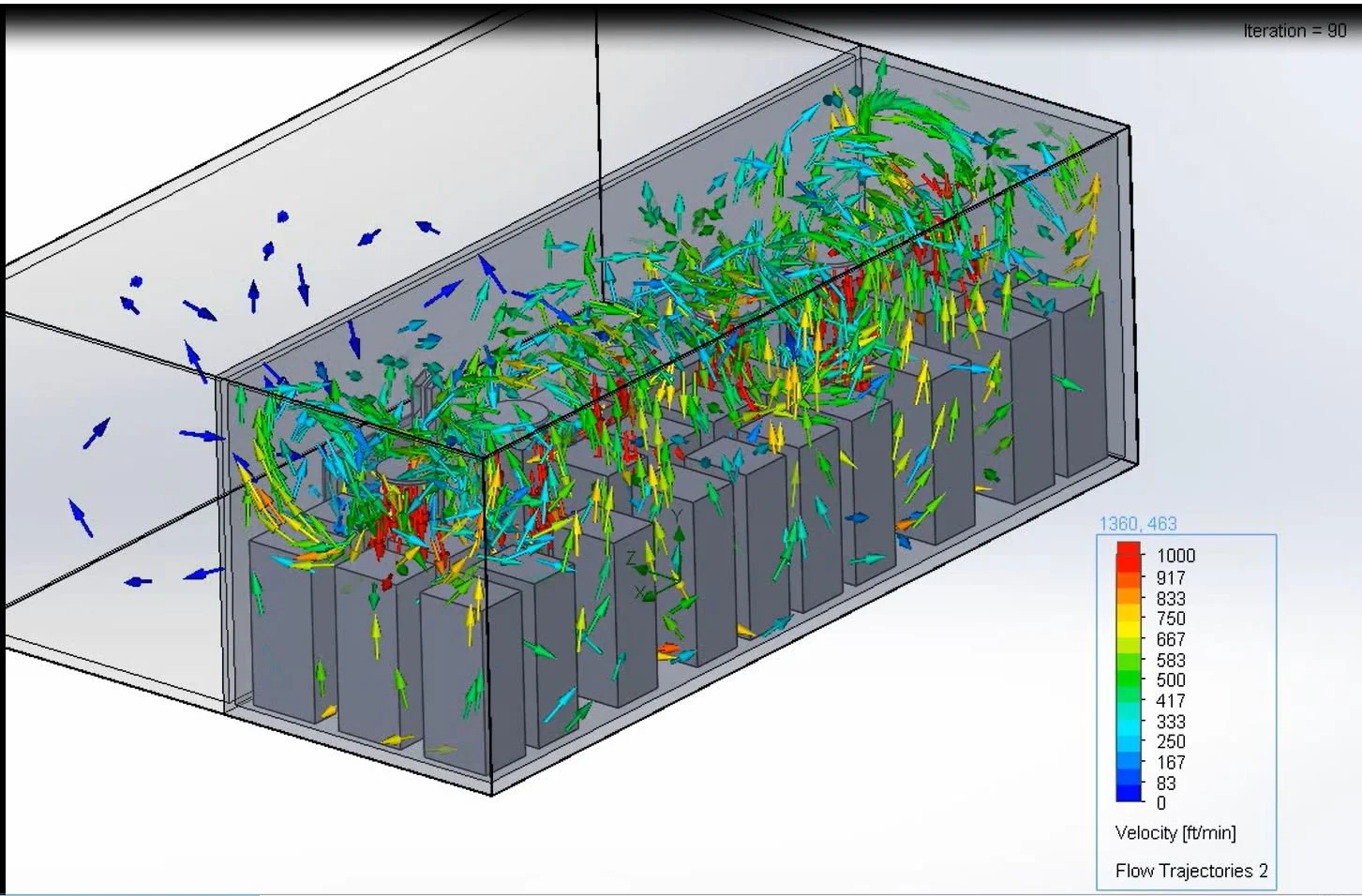

Our team of seasoned engineers applies advanced modeling techniques—including finite element analysis (FEA) and computational fluid dynamics (CFD)—to optimize system design for thermal performance, structural integrity, and process efficiency.

To ensure the highest level of performance, our in-house industrial test lab enables real-world validation of customer products and processes prior to system fabrication.

This empirical approach ensures the final equipment is fine-tuned for optimal throughput, energy usage, and finish quality—reducing project risk and maximizing ROI.

For over 60 years, TEC Process has delivered high-performance, custom-engineered solutions for industrial paint and drying applications.

Our track record of success and long-standing customer partnerships speak to the reliability, precision, and value we bring to every project. Whether you're implementing a complete finishing system or upgrading an existing line for improved performance and efficiency, TEC provides the technical depth and engineering expertise to help you achieve your production goals.

-

Turn-Key Essentials

Thermal Engineering Corporation designs and manufactures all equipment necessary for total turn-key flexibility. -

Enclosed in Quality

TEC® manufactures all types of spray booths and enclosures, from environmentally controlled booths to prep booths, inspection booths and flash tunnels. -

The Right Treatment From The Start

Proper pretreatment creates a clean, refined surface essential for adherence and durability of finished coatings. TEC® manufactures a complete line of pretreatment options to meet the individual requirements of all substrates. -

Two Steps to a Perfect Finish

The RadiantWall™ and Turbulator® Ovens compose a total system engineered to sustain a clean environment so vital to flawless finish. The TEC® system not only provides a dirt-free enclosure, but also offers savings in time, energy and floor space. -

TEC® designs complete turn-key powder systems, including the powder booth, guns, and environmental room with conditioned air and humidity controls.

-

We Keep It Moving

Material handling equipment is critical to almost every paint application system. TEC® provides virtually any type of conveyor to keep your system moving with maximum efficiency. Decades of experience with high temperature conveyors ensure your process moves with smooth efficiency for a long, trouble-free lifetime. -

E-Coat Systems

TEC® will design, engineer, manufacture and install a complete Electro-deposition coating system for your needs. We incorporate the best technology available to build a system that is custom-engineered for your products.